Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

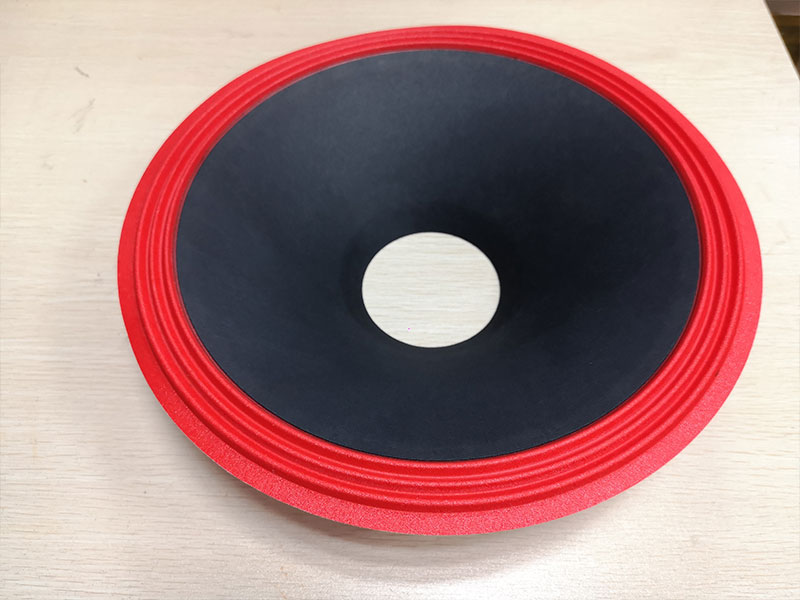

In audio equipment, the speaker is the core of the entire system, and the speaker cone is an important part of the speaker diaphragm, which directly affects the expressiveness of the sound. A high-quality cone can make the bass of the audio system deeper, the midrange fuller, and the treble clearer. Today, let’s take a deep look at the role, material, production process and impact of the speaker cone on the sound quality.

📢 What is a cone?

The cone is the key component responsible for sound propagation in the speaker. It converts electrical signals into sound through vibration. The rigidity, quality, damping characteristics, etc. of the cone will directly affect the sound quality of the speaker. Therefore, it is crucial to choose high-quality cone materials and reasonable design.

🔬 Selection of cone materials

Different cone materials will affect the style and expressiveness of the sound. The following are common cone materials and their characteristics:

✅ Pure pulp:

Common materials for traditional speakers, lightweight, easy to shape, natural and warm sound.

Suitable for mid-high frequency units, with soft and delicate timbre.

✅ Composite fiber (such as cotton fiber, bamboo fiber, mica, etc.)

Enhance rigidity, improve low-frequency response, and make bass more solid and powerful.

Suitable for full-range units and bass units, reduce distortion and improve sound quality.

✅ Carbon fiber cone

It has ultra-high rigidity and lightweight characteristics, improves transient response and reduces energy loss.

Suitable for high-end audio systems, providing more accurate sound performance.

✅ Coated cone (such as nano coating, waterproof coating)

Improve the durability of the cone, enhance moisture and mildew resistance, and is suitable for outdoor audio, car audio, etc.

The coating thickness can be adjusted according to needs to optimize the tone.

⚙ Cone production process

High-quality cones need to go through a strict production process to ensure that every detail is accurate.

1️⃣ Pulp ratio

Use different proportions of pulp and fiber materials to mix suitable rigidity and damping characteristics.

2️⃣ Molding

Through high-precision molds, the pulp is made into a paper cone of a specific shape to ensure consistency and stability.

3️⃣ Drying treatment

High-temperature curing is used to make the paper cone more durable and prevent moisture and deformation.

4️⃣ Surface treatment

Special coating treatment (such as nano coating, waterproof coating, etc.) is performed to improve the weather resistance and acoustic properties of the paper cone.

5️⃣ Acoustic testing

Each paper cone undergoes rigorous audio testing to ensure that it can maintain excellent sound performance at different frequencies.

🎵 The impact of paper cones on sound quality

Different paper cone designs will bring different sound quality styles:

🔊 Low-frequency performance: Paper cones with high rigidity and moderate weight can provide solid low-frequency response and enhance the submergence of bass.

🎼 Mid-frequency performance: The use of high-quality composite fiber paper cones can make the human voice fuller and more natural, and enhance the thickness and layering of the sound.

🎶 High-frequency performance: The lightweight and rigid paper cone can make the high frequency clearer and brighter, improve the resolution, and make the sound more delicate.

📌 Our advantages

🔹 High-quality materials: Select high-quality pulp and fiber materials to ensure the excellent sound quality performance of the paper cone.

🔹 Precision manufacturing process: The use of advanced production equipment ensures the consistency and high precision of each paper cone.

🔹 Strict quality inspection: All products undergo strict acoustic testing to ensure stable product quality.

🔹 Customization support: Different sizes, materials, edge designs and thicknesses can be customized according to customer needs to meet various audio system requirements.